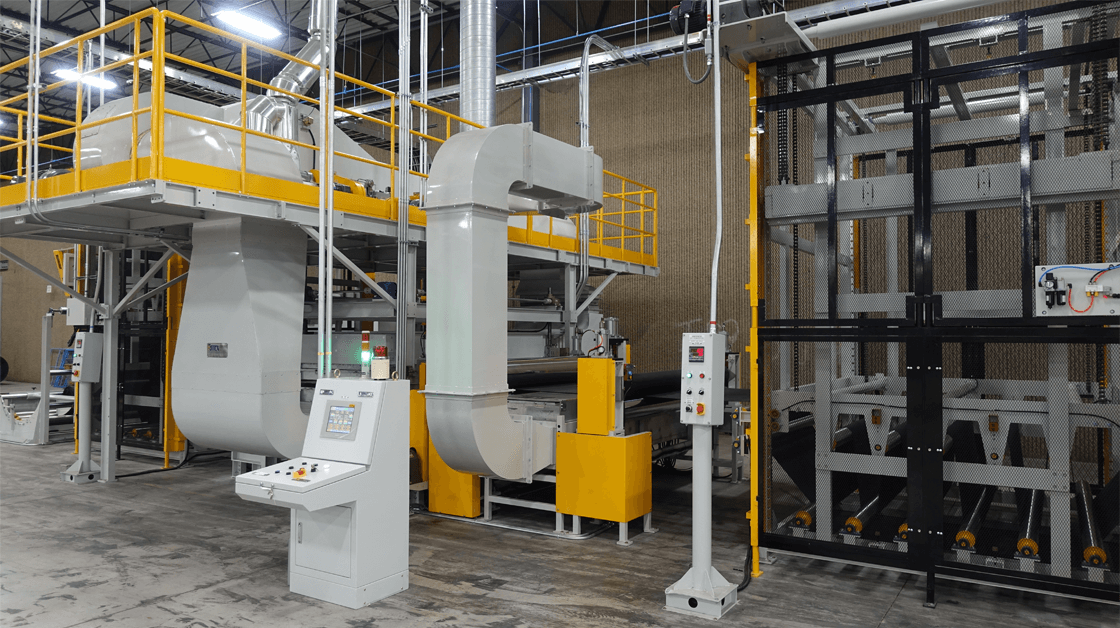

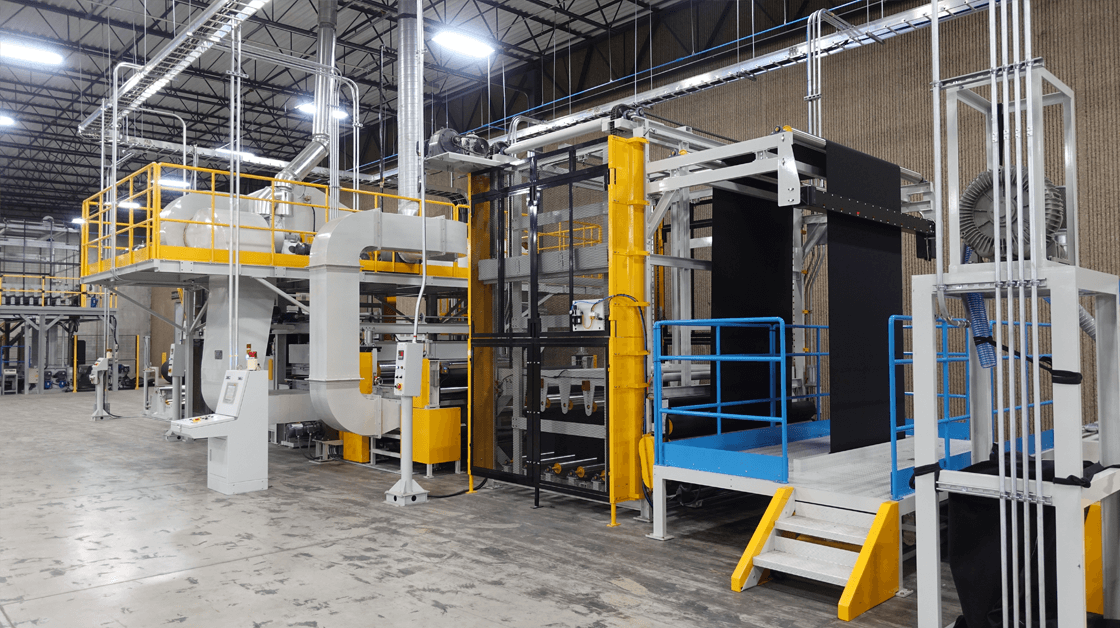

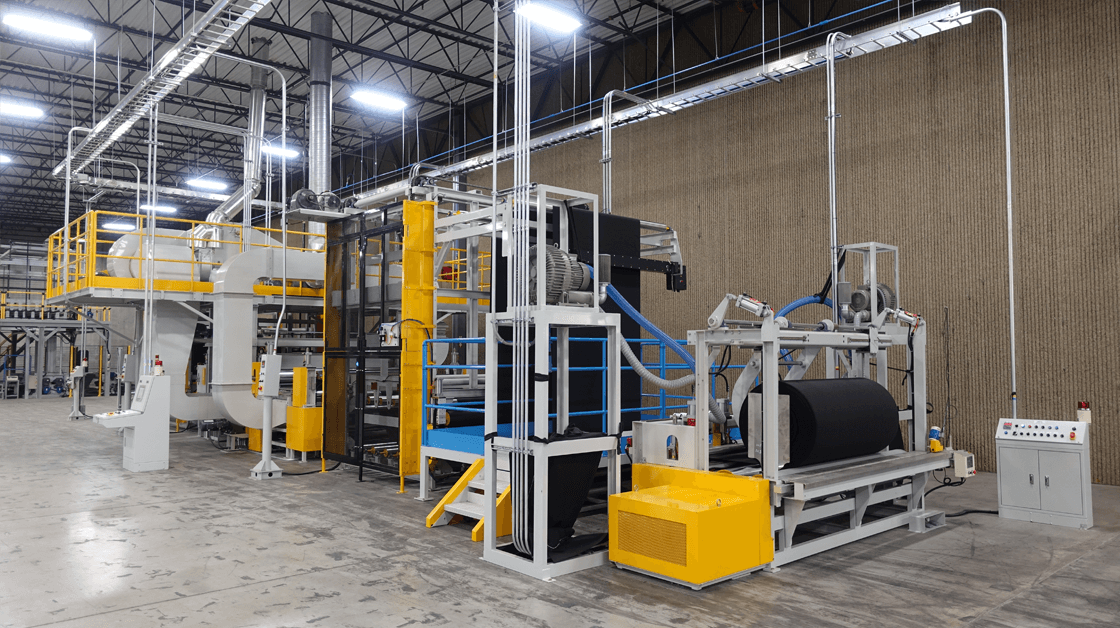

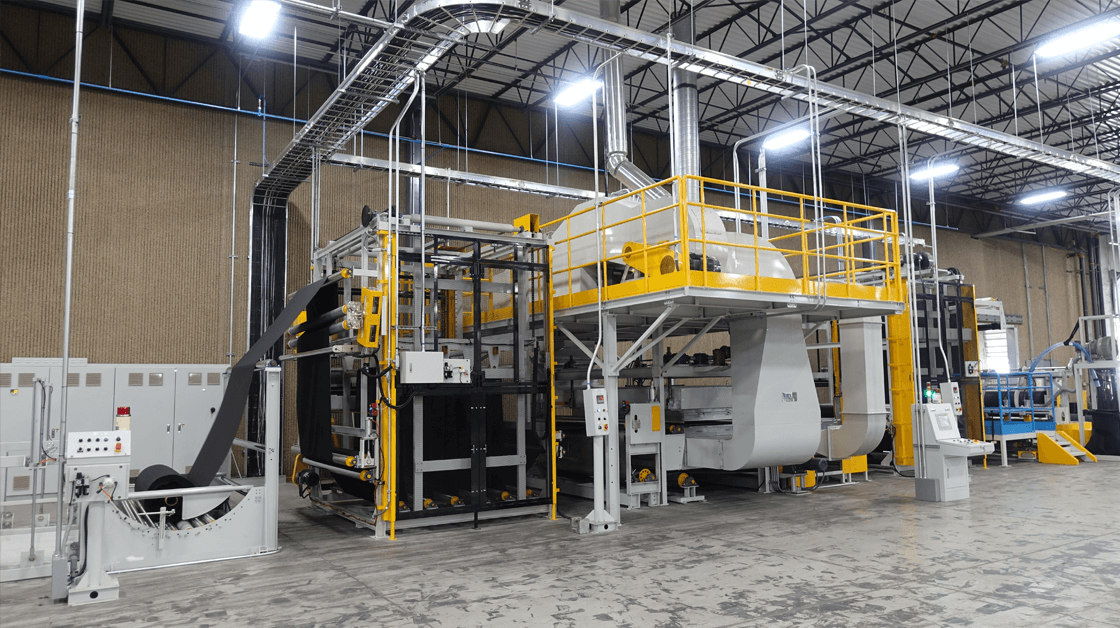

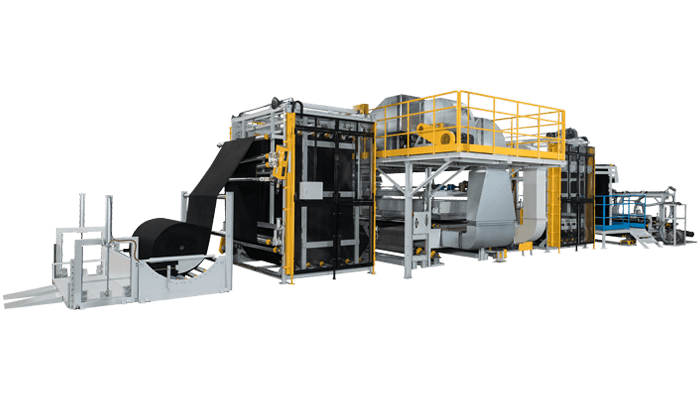

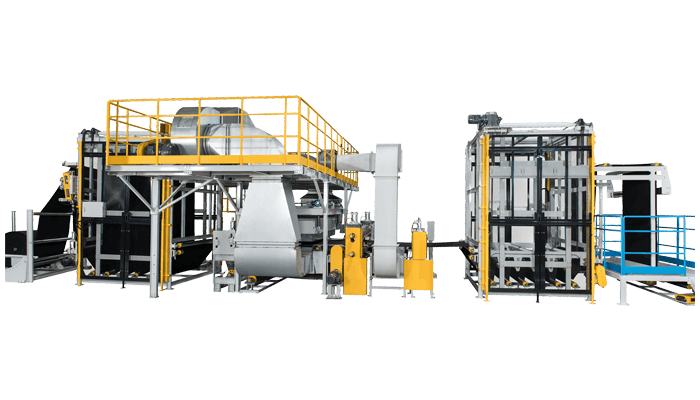

Function

Mainly apply for the nonwoven fabrics after the process of needle punching (e.g.: automotive carpet). The design of air flow through the fabric to make the fabric formed via heat melting reaction. This is able to link in line with the front stage machine for whole line production, but also able to be off line for independent production. The most energy saving design for needle punching process.