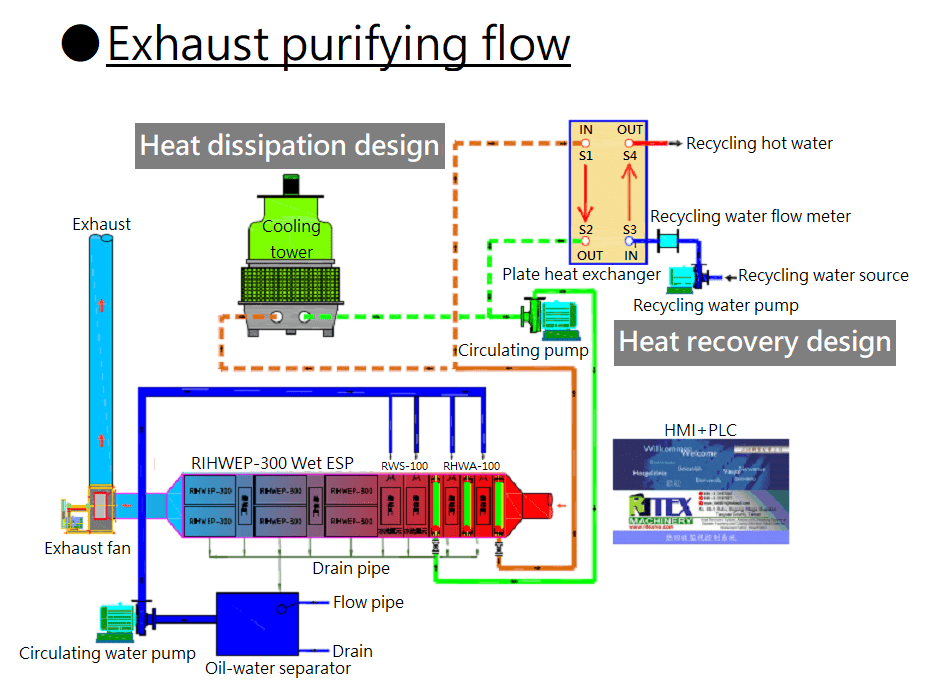

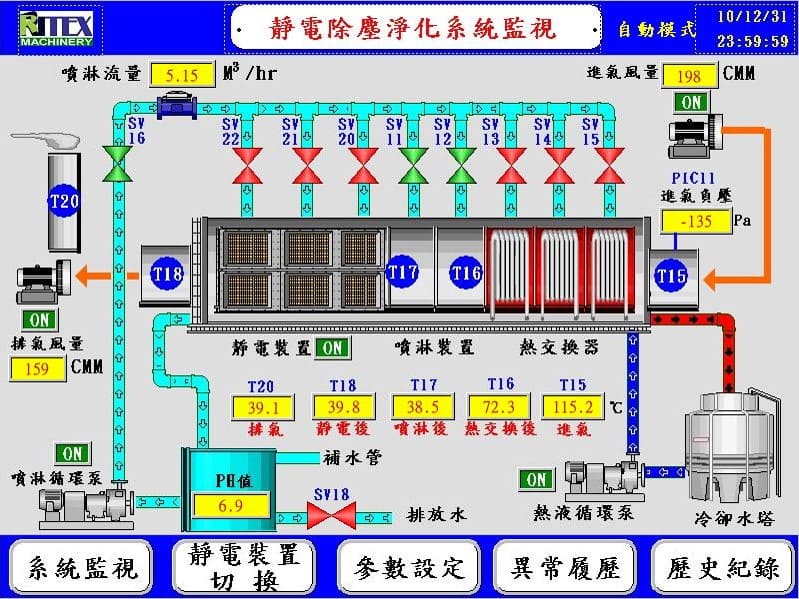

Control method:

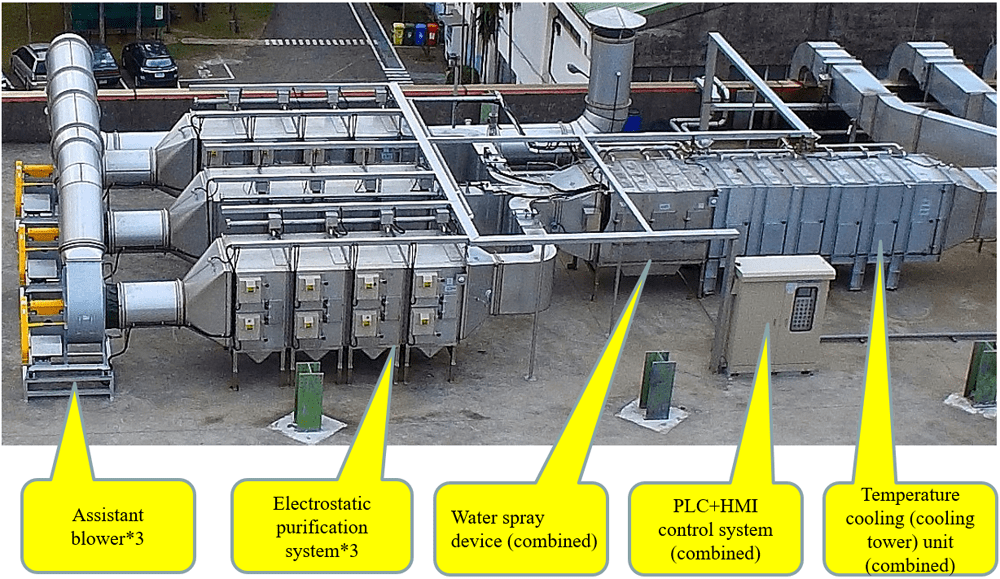

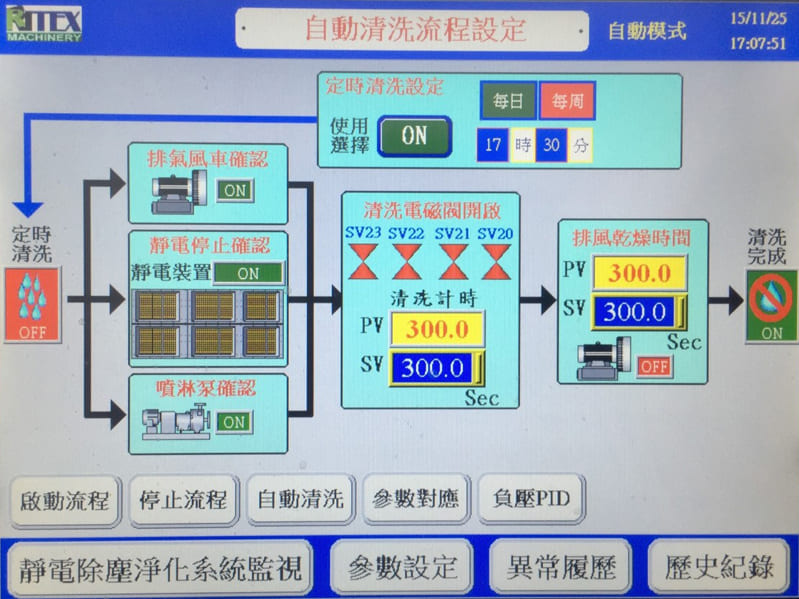

by PLC+HMI auto control and recording system

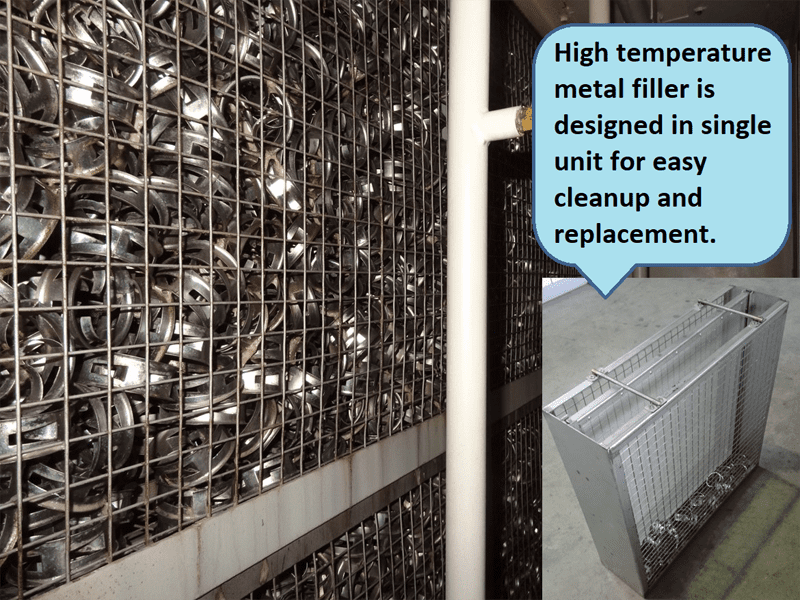

- Heat absorption single unit adopts heat exchange tubes which are fully covered with aluminum fins. The heat absorption efficiency is good. Access door between single units is designed for easy maintenance.

- Water spray design can setup for regular cleaning (controlled by PLC).

- Can combine with plate heat exchanger for heat recovery (optional).

- Temperature detection for fire alarm system.

- Heat dissipation type adopts cooling tower (standard).

- Collecting oil and water into oil-water separation tank to efficiently eliminate the oil dirt.

Heat recovery type: High efficiency gas-liquid heat exchanger, cooling the exhaust heat by heat exchange, then recycle the heat (hot water)

Heat dissipation type:

Cooling by the cooling tower

Purpose and Operating conditions:

Heat recovery type: Exhaust gas temperature (140~180℃). Design to recovery hot water (50~60℃) for process use. At the same time, cooling exhaust gas temperature to under 80 ℃ to effectively condense gas mist into liquid material particles.

Heat dissipation type: Exhaust gas temperature (140~180℃), Design to cool down exhaust gas temperature to under 50 ℃ by cooling tower to effectively condense gas mist into liquid material particles.