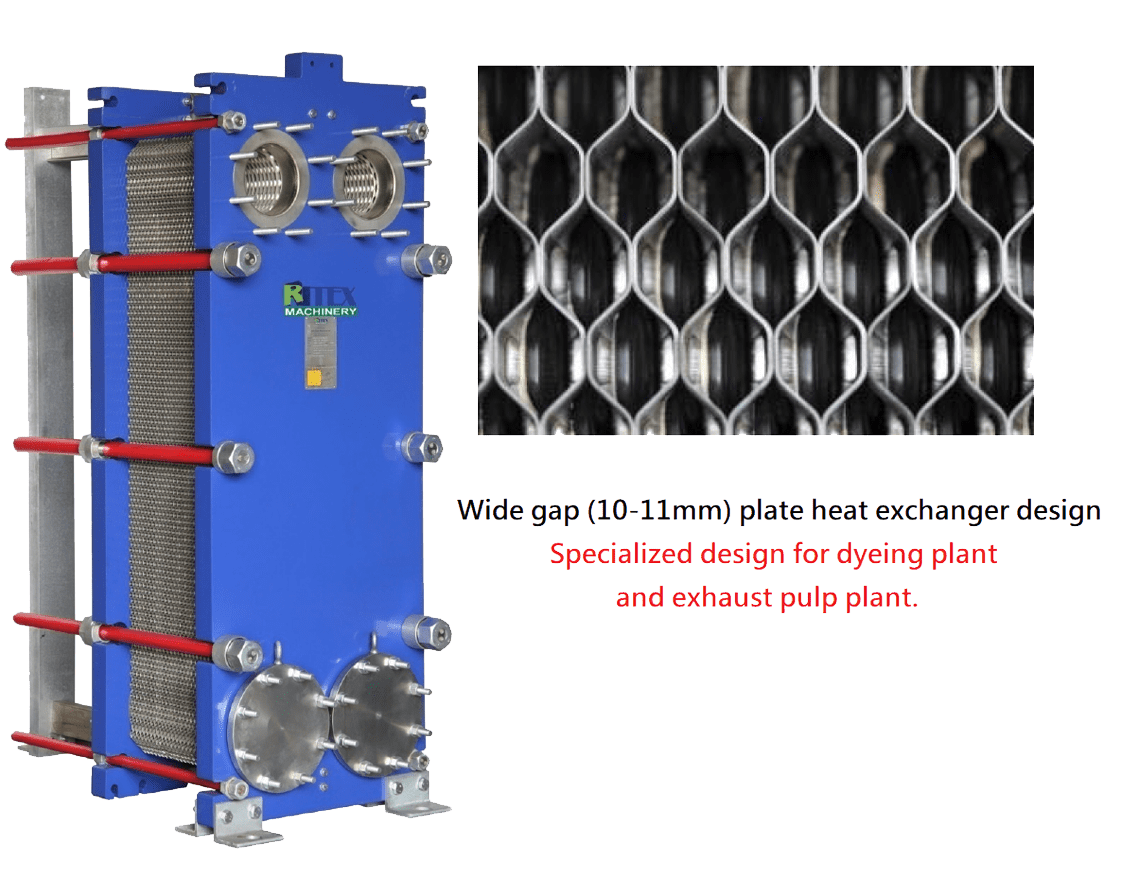

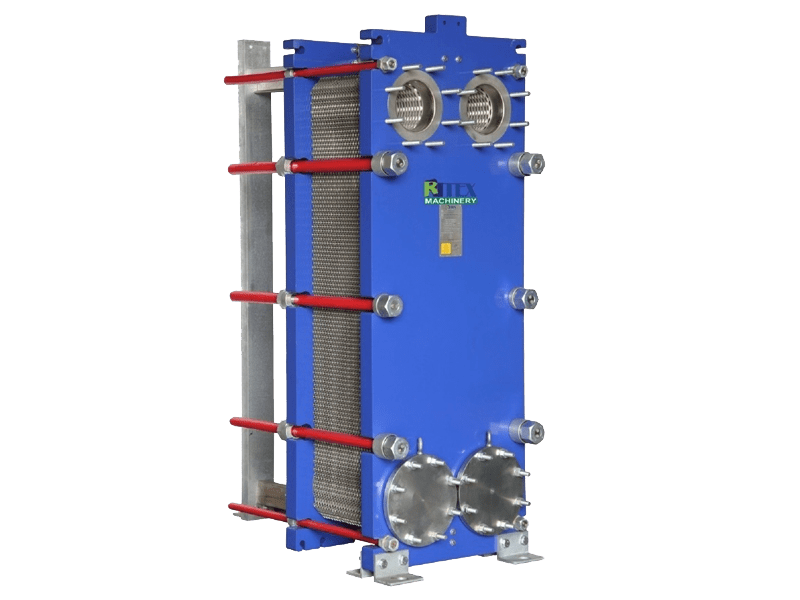

Design concept

Utilize the design concept of waste hot water emission shunt in dyeing process to recover 60~70℃ waste hot water with high-efficient plate heat exchanger specialized on waste hot water recovery. Recycling water temperature can reach 50~60℃ and can be used as processing water to reduce the production energy usage to reach the optimum efficiency. At the same time, the waste hot water temperature can be reduced to under 35℃ in order to comply with the inlet water temperature requirement of biological treatment of waste water and save the power of cold water tower.