Purpose

To remove the primary pollutant, NOX ,which can undergo chemical reactions in the atmosphere to form secondary pollutants, such as Photochemical smog, in order to reduce the production of photochemical pollutant in Earth‘s atmosphere to protect Earth.

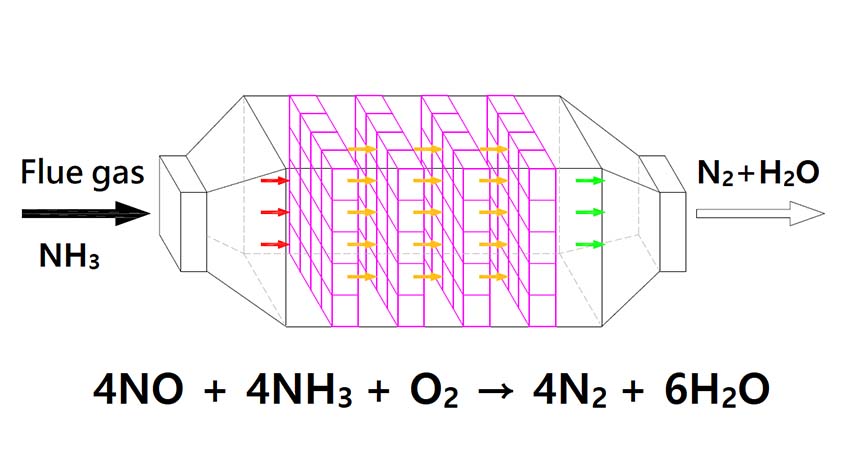

Reaction principle

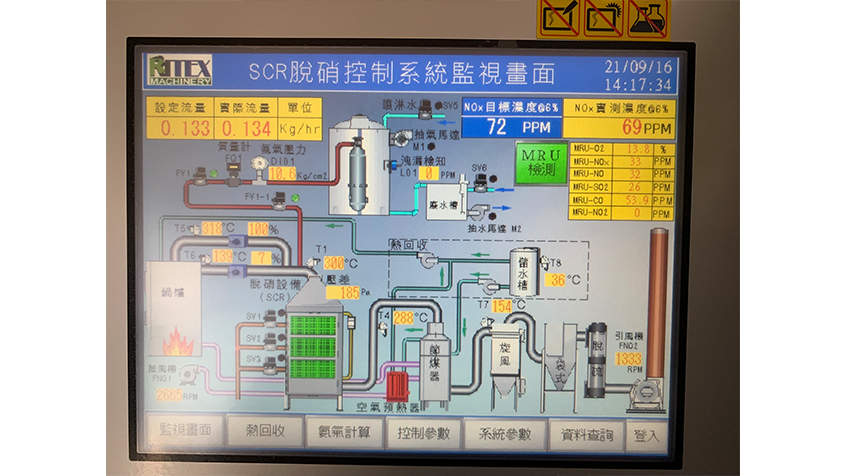

Selective Catalytic Reduction (SCR). Use NH3 as reductant agent and inject it into the system in a certain proportion (NH3/NOX) (usually equivalent to the NOX concentration) and fully mix with the exhaust gas. In the condition of Oxygen existence, after the catalytic reaction of catalyst, the NOX would be reduced to harmless N2 and H2O.The main reaction of NH3 –SCR can be expressed as:

4NO + 4NH3 + O2 → 4N2 + 6H2O